The Definitive Guide To Rain Gear

We get so many questions on rain gear and know a lot of hunters like to throw around opinions while sitting around in hunting camp about what gear works the best. Let’s dive into the details for a hard look at reality and truths as it pertains to rain gear.

There are no shortages of “waterproof” jackets and pants on the market. It can be overwhelming at times to decipher all the marketing jargon, facts, and figures. What constitutes “waterproof”? How are rain systems meant to work? What are the limitations and compromises you may face when buying a 2 or 3-layer system?

We know first hand the complexities and confusion of finding the perfect pieces for your chosen pursuit, and we want to share the details on how rain gear is meant to work and the intricacies on why it sometimes doesn’t. This will allow you to cut through the bullshit and find the right type of gear for your next trip.

The Big Trade Off

Despite what many people think, being “waterproof” is not as black and white as it seems. “Waterproofness” is measured on a spectrum, and it goes hand-in-hand inversely with breathability (also referred to as Moisture Vapor Permeability/Transmission or MVP/MVT). So as one attribute gets better the other tends to get worse. It’s a trade-off. There are materials and fabrics that are 100% waterproof, but with these kinds of fabrics, the breathability is basically 0 and for most apparel, that’s very impractical. You can get outfitted in a rubberized suit and stay dry from rain but you're going to sweat your ass off so pick your poison. The most effective and efficient rain gear is going to limit the amount of water coming in, but allow you to dump out heat and regulate body temperature.

So, how do you find the perfect piece of rain gear? First understand that there are different pieces designed for different levels of activity and anticipated moisture levels. This will play a significant role in how robust the rain gear needs to be to manage moisture. For instance, are you on a multi-day, backcountry or mountain hunt logging 10-12 hours of walking/climbing with all day soakers, or are you heading out for a day hunt with a chance of a pop up shower? Totally different types of hunts and conditions, not necessarily needing the same equipment.

These garments are investments. Quality pieces are going to cost more because they cost more to make, just a simple fact. So which is right for you and your hunt? How do you make sense of what all is on the market? To understand the terms and equipment better, we’ve broken down the construction of rain gear, so you can make a more informed decision.

Waterproof Construction- Membranes, Layers, and Coatings

To build the right waterproof and breathable garment, it requires the perfect combination of membranes, layering, and construction. A membrane is just another word for a thin layer of material or film that keeps precipitation out while allowing perspiration to exit. The types of membranes become very important for the breathability aspect of your rain gear. When it comes to rain gear, there are basically two types of membranes used: microporous membranes and/or hydrophilic membranes.

The microporous membrane is a direct physical barrier with microscopic holes allowing the small moisture / water vapor molecules from your sweat to physically escape out of the jacket, while keeping the larger water molecules from the rain from coming in. Think of it like a window screen. Small particles can pass through the holes while larger particles are stuck on the outside of the screen. On the other hand, a hydrophilic membrane takes a slightly more “chemical” approach through ion attraction. Hydrophilic, meaning “water-loving” in Greek, may seem counter-intuitive, but this membrane effectively attracts the water vapor inside your jacket, pulls it away from your body and to the outside of your gear through what is known as differential pressure. This means it’s warmer inside the garment, which aids in driving the water vapor to the outside. This membrane also provides good waterproofness in our typical climate zones here in the States, compared to the extremely hot, humid, and rainy zones found in parts of Asia.

Layering is next. So we have all heard of a 3-layer system, but what does that mean? Simply stated, layering is when a membrane is laminated to various layers of a fabric. Companies either choose to laminate the membrane to an outer face fabric and/or potentially to an inner backer as well, whose thickness and density also affect the breathability. Whichever construction is chosen is how we get the terms 2, 2.5, and 3 layer system. So which one is right for you? We are about to drop some knowledge.

2-layer garments are constructed using a face fabric laminated directly to a membrane, typically more breathable since no backing. In this system, a lining or “loose layer” is added to the inside of the jacket to protect the membrane of the laminate from wear/ abrasion and contamination from body fat, dirt. A ski jacket is one good example of 2-layer design, as there is insulation in between the waterproof outer and the lined inside. This type of garment is typically soft and comfortable, but by adding an additional lining layer it can make it heavier and less packable.

2.5-layer garments are also seen on the market more frequently, but how does a half layer work? These laminates contain a face fabric, a membrane, and a protective coating added to the backside of the membrane facing your body, that also protects the membrane from contamination and moderately from abrasion. These are usually a bit lighter and softer, but a bit less durable and more easily compromised by gear underneath through scratches or punctures.

Lightweight and packable jackets exposed to little physical stress (backpack wear, contact with stone, branches, etc) such as cycling or running jackets are a good example where this type of construction and materials are ideal for. Emergency jackets that are carried along as backup layers are another.

Finally, we have the 3-layer. 3-layer systems are quite common in the outdoor and hunting industry and are an ideal solution for compact/light but durable laminates. 3-layer systems come with an inner backer towards the backside of the membrane so the membrane is placed safely protected in between 2 fabric layers. This third layer makes the fabric a bit crisper/stiffer, but with added protection for the membrane on the inside. The big plus on this construction is that the laminates are generally durable but at the same time light and packable and therefore commonly used in the mountaineering/ outdoor markets as the protective (rain/ wind) layer of a flexible layering system. There are many offerings of different options from super light to sturdy, to static, and 4-way stretch, each designed to accommodate various intended purposes.

CANIS, for example, uses a light, high-tenacity stretch nylon with a highly-breathable, soft-type membrane with a knitted backer to get the best combination of weight, comfort, comparably silent and high reliability.

The Outer Layer

The outer or shell layers are designed to manage the durability and longevity of the garment. Regardless of the membrane used, the outer layer of the garment is what is facing the elements and is important for membrane protection. We’re talking damage from wear, rubbing from gear, punctures from thorns and other things. Once damage reaches the membrane, your system is compromised. Lighter rain gear, as to be expected, is often made with lighter face layers, and while they may pack-down lighter and be a bit more breathable, the risk of penetration is higher and should always be considered.

Since your face layer is your first line of protection, the materials used should be a consideration when choosing your gear. For instance, the use of nylon vs polyester as an outer layer has trade-offs. Polyester is generally a less expensive option and is easier for companies to print patterns on, but nylon is more durable, a bit more costly, and more difficult to be printed.

No matter the outer layer fabric, it is treated with a DWR (Durable Water Repellent) finish to aid in the water resistant nature of the garment. Imagine this coating like micro hairs that stand up on the fabric keeping water off the surface. This treatment also plays a supporting role to keep water away from the breathable membrane (i.e. window screen). DWR is absolutely needed, specifically with hydrophilic (moisture attracting) membranes. In heavy rain situations, this finish helps the face fabric avoid getting saturated to the point where water is being pulled back through the membrane into the jacket. If you remember, hydrophilic membranes absorb and transmit vapor from the inside of your jacket (micro climate) towards the outside using the capillary effect and differential pressure. This membrane system works best in lower humidity and cooler conditions (vs. humid and hot). The big benefit of a hydrophilic membrane is that the moisture vapor at the inside is rapidly absorbed and transferred creating a dryer micro climate and therefore a greater wearing comfort. In times of low differential pressure where outside temperatures are above body temperature and high humidity, there is a risk that the system reverts and transmits towards the inside of your system. This however is seldom the case in North America and Europe, however can apply in Asia- Pacific regions.

Construction is the final piece of the puzzle. Proper construction and design of these fabrics is the best way possible to achieve the highest performance. The devil is in the details, and quality design and clever construction are absolutely essential for a high-performance piece. On a high-quality piece, all seams, pockets, and zippers will be sealed and areas of ventilation will be large and plentiful. Mistakes in construction and design in these areas can spell trouble for a garment no matter the price point.

Take Care of Your Gear So It Can Take Care of You

The previously mentioned DWR finish helps keep the surface dry longer and aids in maintaining the functionality of the membrane. No matter how much money you have spent on your gear, it is imperative that you properly care for your garments. The more you wear your technical rain gear the more it is going to accumulate dust, dirt, and particles that compromise the integrity of the piece. To increase life and performance, special care must be taken. Gently rinsing the garment every now and then with a Tech Wash instead of a detergent powder will keep debris off the fabric. Tumble drying on low heat or using a low-temperature iron is the way to dry your piece. Without question, fabric softener should never be used as this kills the DWR treatment.

In addition, the DWR treatment is sensitive to mechanical abrasion, therefore it is recommended to use a Tech Proofer to reactivate the DWR every now and then, when you feel the water repellency is compromised. Again, no matter how much you pay for your rain gear, whether it is “top of the line” or a value piece, the longer and more it is used, it is going to lose its water shedding ability. 9 times out of 10 when you think you have a failure in your rain gear and water is “seeping through the fabric” either the gear is not breathing properly or the garment needs to simply be washed and treated with tech proof. You have to care for it, maintain it, and keep it clean! A simple $25 investment in a good Tech Care Kit can save you a lot of time and heartache. Check out the full line of apparel and leather care products from Storm that we use, recommend, and sell here.

Breaking Down the Numbers

Alright, we understand the construction, the layers, the membrane, but what do all these damn numbers mean? Marketing departments love to inundate the customer with details, selling features, and really big numbers. After all, bigger is always better right? It’s true in a lot of things but you need to make sure you are comparing apples to apples. So let’s take a look at how to compare the different product ratings and really break down the numbers of the products on the market.

Comparing waterproof products, you will see lots of different measurements and references to testing procedures and possibly some obscure acronyms for good measure. The good news is that most companies are using legitimate tests and procedures to make sure their product is of high quality. The bad news for the consumer is there really isn’t a uniform standard of testing that all companies use. To help you with your deciphering of the data, here are a few common terms and measurements of what “good” looks like.

“Hydrostatic Head” is a term used to quantify the level of waterproofness of different textiles (measured in millimeters). To simplify, it is measured by applying water pressure to the surface of the fabric and identifying at which point it lets water seep through. Here is what the numbers mean to you:

A waterproof rating around 10,000mm is common in performance wear used in more aerobic activities like trail running. You’ll stay dry in light to moderate rain for shorter durations, but is liable to leak if wearing a backpack or other gear adding additional pressure to the garment.

A waterproof rating around 20,000mm usually provides the typical great balance for hunters and outdoor enthusiasts for most of the year. It’s middle ground giving more rain protection than the lighter 10,000mm jackets and more breathability than the 30,000mm garments.

A waterproof rating around 30,000mm means these garments are made for the roughest, wettest conditions. While these types of jackets often lack breathability - they still prove extremely valuable for slow-moving hunters and ice-climbers who don’t expect to sweat so much.

The second important rating system is for breathability, aka the Moisture Vapor Permeability/Transmission Rate (MVTR). You’ll see this measured by the number of grams of sweat / water vapor passing through a square meter of fabric in 24hrs. These ratings tie back to your expected activity level.

5,000-10,000 g/m2/24h – A rating in this range means the garment is typically suitable for low-output activities and general outdoor use. This is not ideal for fast-moving, high-intensity hunts or activities as it doesn't let out sweat as efficiently.

10,000-15,000 g/m2/24h – A rating in this range means the garment is built for active use in high-output activities.

20,000+ g/m2/24h – The best bet for use in warmer climates or for more intense aerobic activities like trail running or ski-mountaineering.

What’s On The Inside That Counts

As we have said, it is all about balance and no matter the brand or the design, there are going to be trade-offs. You have to keep water out, you have to let your body “breathe”, and you have to do this comfortably. Almost as important as selecting the right rain gear is making sure the layers underneath support managing your body’s micro-climate. You can have the best performing rain gear on the planet, but without high-performance base and mid layers, you essentially just pissing in the wind (and that’s not a good thing).

Micro-climate management… that is a fancy way of saying regulating the temperature and moisture levels around your body inside of your outer layers. How are your layers keeping your body at the perfect temperature while also wicking away any perspiration? Proper microclimate management can really add to the effectiveness of the rain gear you buy. Based on your activity level and how cold of climate you expect, you will want to control the permeability of each individual layer - moving base layers with higher breathability/moisture management next to your skin and adding mid layers that regulate body temperature. The closer that moisture remains to your body, the more uncomfortable it can become, so it needs to be transported away from your body. That’s why it’s imperative your base layers need to contain fabrics with moisture-controlling properties like Merino wool.

We know we have thrown a lot at you, but in fairness, there is a lot to consider. At the end of the day, understanding how the features work, finding the best balance for your specific activity level and expected precipitation will help you find the perfect rain gear for your next adventure. Again, no matter what you choose for the outer layer, what you are wearing underneath is almost just as important.

The Best Rain Gear on The Planet

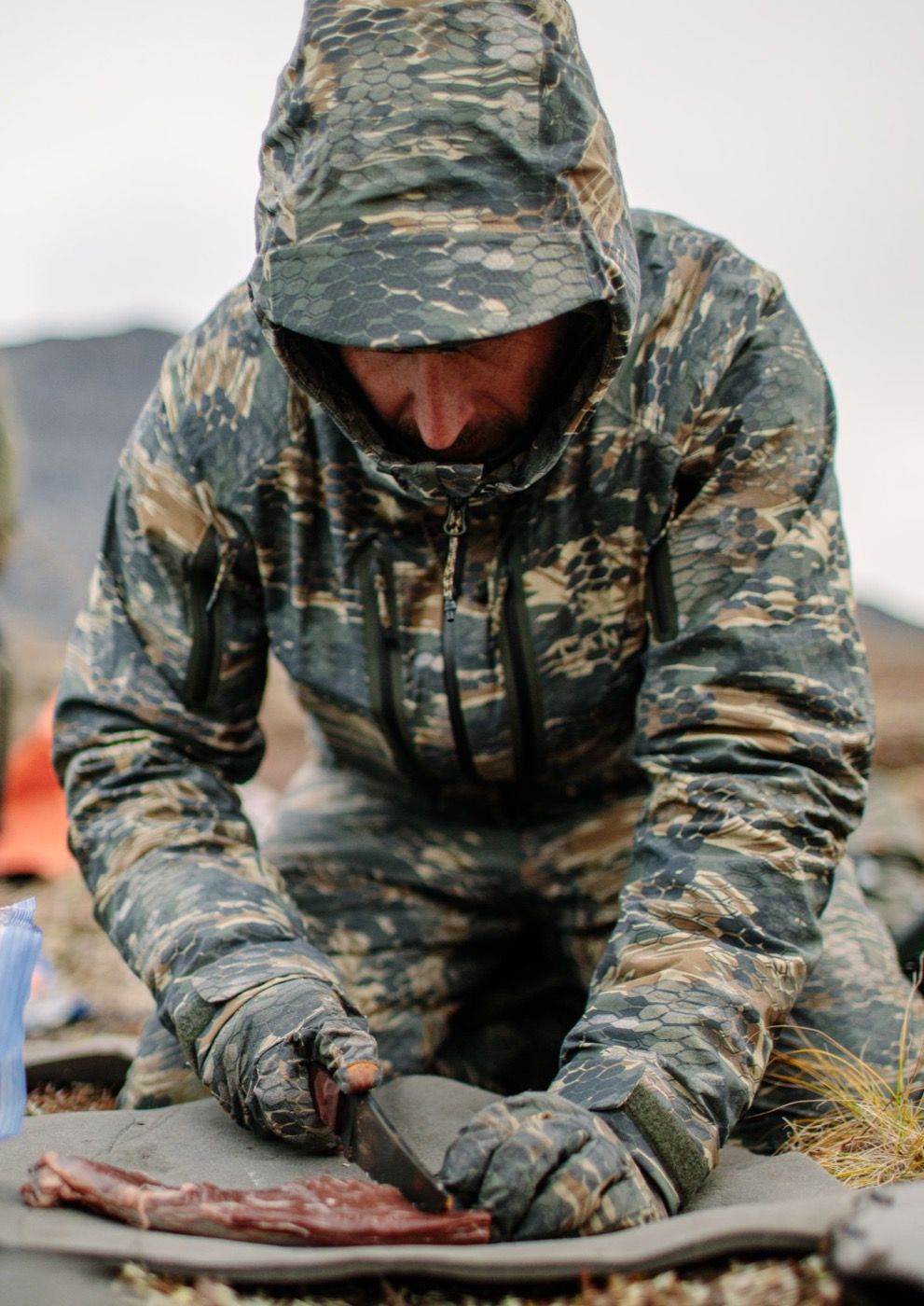

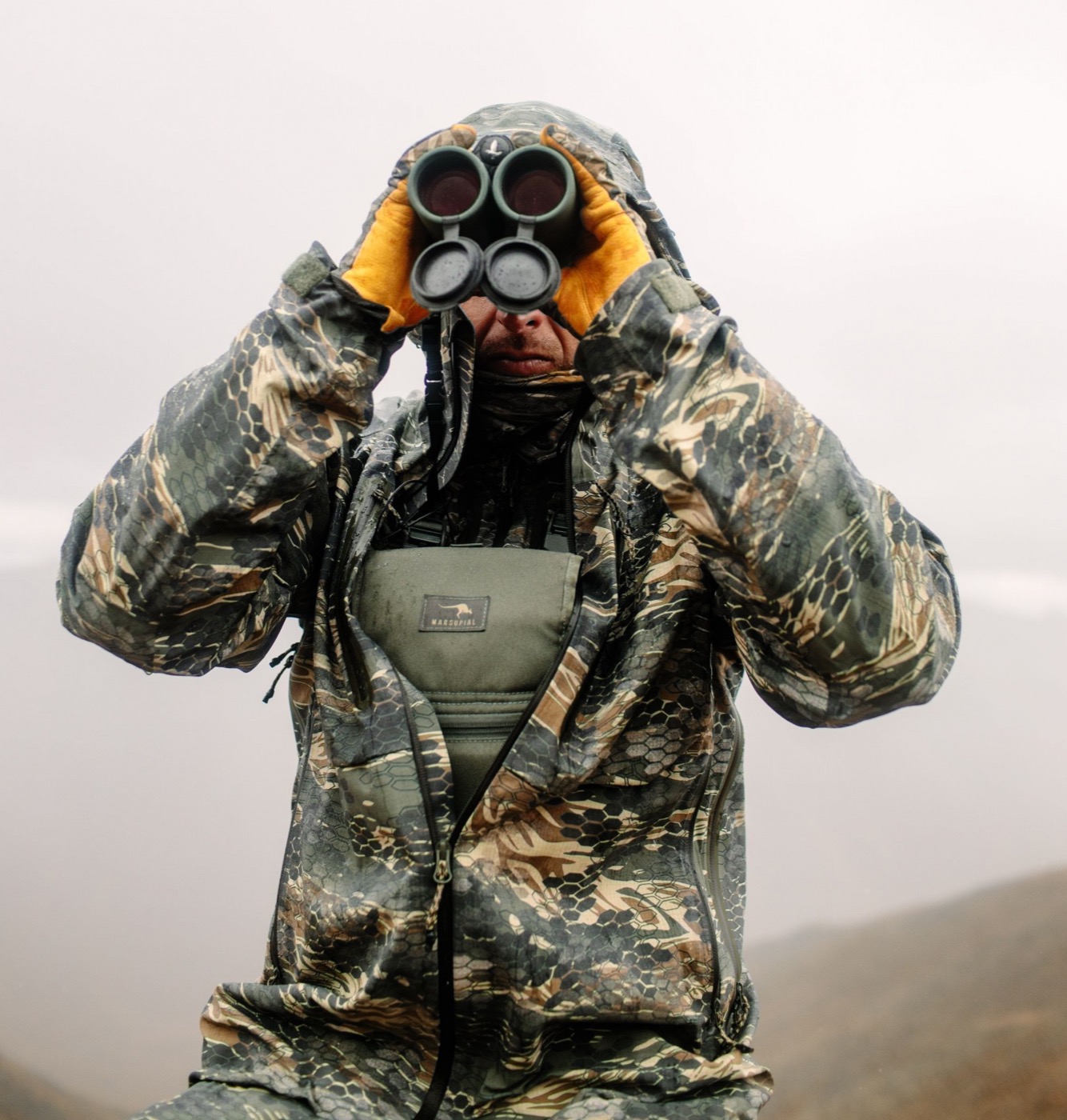

From a CANIS perspective, we have two options to choose from in our current lineup. The Nunavut is a 3-layer, fully-loaded workhorse of a jacket and pants combo built for enduring all day rains when you still need to charge hard from sunrise to sundown. Our Design Team chose a combination of construction, layers, and membrane that is the perfect balance of breathability 24’000gr/m2/24h (inverted cup) and water soundness <20’000mm (JIS Norm) at a weight you don’t mind wearing all day.

The Wapiti is a reduced jacket with minimalistic features, that utilizes the same high-performing

3-layer laminate weighting just 10oz. Its lightweight construction is perfect for throwing in your pack and keeping you dry for a shower or two during the day. No matter which you choose, combining with our Tahr Merino base layers and Chamois Fleece mid layers is crucial for microclimate management and overall comfort.

Nunavut Rain Jacket

Weight: 14oz/ 395gr

Construction: 3 layer laminate

Material: Lightweight 100% High tenacity nylon (PA66) 3L stretch laminate/ high performance hydrophilic PU stretch membrane/ silent PES tricot backer

Membrane Waterproofness: >20’000mm

Membrane Breathability: 24’000gr/m2/24h

Standard: JIS L 1092, JIS L 1099 B1

Nunavut Rain Pants

Weight: 15oz/ 425gr

Construction: 3 layer laminate

Material: Lightweight 100% High tenacity nylon (PA66) 3L stretch laminate/ high performance hydrophilic PU stretch membrane/ silent PES tricot backer

Membrane Waterproofness: >20’000mm

Membrane Breathability: 24’000gr/m2/24h

Standard: JIS L 1092, JIS L 1099 B1

Wapiti Rain Jacket

Weight: 10oz/ 285gr

Construction: 3 layer laminate

Material: Lightweight 100% High tenacity nylon (PA66) 3L stretch laminate/ high performance hydrophilic PU stretch membrane/ silent PES tricot backer

Membrane Waterproofness: >20’000mm

Membrane Breathability: 24’000gr/m2/24h

Standard: JIS L 1092, JIS L 1099 B1